Nhanganyaya

This service manual provides detailed instructions and procedures for the maintenance, repair, and overhaul of the Massey Ferguson 1105 tractor. It is intended for qualified service technicians and individuals with a thorough understanding of tractor mechanics. Adherence to the procedures outlined in this manual is crucial for ensuring the safe and efficient operation of the tractor.

The manual is structured into several parts, each focusing on specific systems or components of the tractor. Always refer to the relevant section before performing any service or repair work.

Figure 1: Cover of the Massey Ferguson 1105 Tractor Service Manual. This image displays the front cover of the comprehensive service guide for the Massey Ferguson 1105 tractor, indicating its purpose as a detailed repair and maintenance resource.

Manual Structure Overview

The Massey Ferguson 1105 Service Manual is organized into distinct parts, each addressing a specific area of the tractor. This structure allows for easy navigation to the required information for maintenance, troubleshooting, and repair tasks.

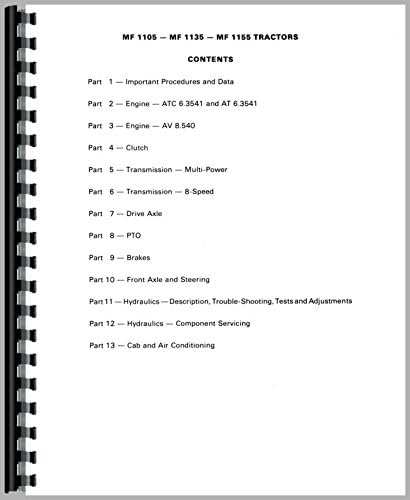

Figure 2: Contents page from the Massey Ferguson 1105 Service Manual. This image shows a page detailing the manual's table of contents, listing major sections such as Engine, Clutch, Transmission, Hydraulics, and more, providing an overview of the covered topics.

- Chikamu 1: Important Procedures and Data

- Chikamu 2: Engine – ATC 6.3541 and AT 6.3541

- Chikamu 3: Engine – AV 8.540

- Chikamu 4: Clutch

- Chikamu 5: Transmission – Multi-Power

- Chikamu 6: Transmission – 8-Speed

- Chikamu 7: Dhiraivha Axle

- Chikamu 8: PTO (Simba Kubvisa)

- Chikamu 9: Mabhureki

- Chikamu 10: Front Axle and Steering

- Chikamu 11: Hydraulics – Description, Trouble-Shooting, Tests and Adjustments

- Chikamu 12: Hydraulics – Component Servicing

- Chikamu 13: Cab and Air Conditioning

Part 1: Important Procedures and Data

This section covers general safety guidelines, recommended torque specifications for various fasteners, and essential data such as fluid capacities and types. Always consult this section for critical information before beginning any work.

Chengetedzo Yekuchengetedza

- Gara wakapfeka midziyo yekudzivirira yakakodzera (PPE).

- Ensure the tractor is on a level surface and properly secured before working underneath.

- Disconnect the battery before performing electrical work.

- Relieve hydraulic pressure before disconnecting hydraulic lines.

Parts 2 & 3: Engine Service (ATC 6.3541, AT 6.3541, and AV 8.540)

These sections provide detailed service information for the specific engine models used in the Massey Ferguson 1105 tractor. Topics include:

- Engine removal and installation

- Cylinder head and valve train service

- Piston, connecting rod, and crankshaft inspection

- Lubrication system maintenance

- Cooling system diagnostics and repair

- Fuel system component servicing, including injector and pump adjustments.

Kutsiva Sefa yemafuta

Regular replacement of fuel filter elements is essential for maintaining engine performance and preventing fuel system contamination. This procedure should be performed every 500 hours of operation or as specified in the maintenance schedule.

Figure 3: Fuel Filter Identification and Sequence of Parts. This diagram illustrates the components of the fuel filter assembly, including the center bolt, O-ring, element seal, filter element, transparent bowl, base seal, and drain plug, along with torque specifications for proper assembly.

Procedure for replacing fuel filter elements:

- Clean the area around the fuel filter assembly to prevent contamination.

- Unscrew the center bolt at the top of the filter.

- Remove the transparent bowl and filter element.

- Clean the filter base and bowl thoroughly.

- Install new sealing rings and a new filter element. Ensure the element is correctly oriented.

- Reassemble the filter, tightening the center bolt to the specified torque (6-10 ft-lbs).

- Bleed the fuel system as necessary to remove air.

Part 4: Clutch Service

This section details the inspection, adjustment, and repair procedures for the tractor's clutch system. Proper clutch operation is vital for smooth power transfer and preventing transmission damage.

- Clutch pedal free play adjustment

- Clutch disc and pressure plate inspection

- Release bearing replacement

- Clutch housing removal and installation

Parts 5 & 6: Transmission Service (Multi-Power and 8-Speed)

These sections provide comprehensive instructions for servicing both the Multi-Power and 8-Speed transmission systems. This includes:

- Transmission fluid checks and changes

- Gear and shaft inspection

- Bearing replacement

- Shift linkage adjustments

- Troubleshooting common transmission issues.

Part 7: Drive Axle Service

This section covers the maintenance and repair of the drive axle components, ensuring proper power delivery to the wheels.

- Axle shaft inspection and replacement

- Differential unit service

- Final drive maintenance

- Lubrication requirements.

Part 8: PTO (Power Take-Off) Service

Instructions for the inspection, adjustment, and repair of the Power Take-Off system, which is crucial for operating various implements.

- PTO clutch adjustment

- Shaft and bearing inspection

- Troubleshooting PTO engagement issues.

Part 9: Brakes Service

This section provides detailed procedures for maintaining and repairing the tractor's braking system to ensure safe stopping performance.

- Brake pedal adjustment

- Brake disc/shoe inspection and replacement

- Hydraulic brake system bleeding

- Parking brake adjustment.

Part 10: Front Axle and Steering Service

This section covers the maintenance, lubrication, and repair of the front axle and steering components, essential for precise control and maneuverability.

- Front wheel bearing adjustment and lubrication

- Steering linkage inspection and adjustment

- Power steering system diagnostics.

Parts 11 & 12: Hydraulics Service (Description, Troubleshooting, Tests, Adjustments, and Component Servicing)

These sections are critical for understanding and maintaining the complex hydraulic system of the Massey Ferguson 1105. They include:

- Detailed description of hydraulic circuits and components.

- Troubleshooting guides for common hydraulic malfunctions.

- Procedures for testing hydraulic pressure and flow.

- Adjustments for control valves and relief settings.

- Servicing of hydraulic pumps, cylinders, and motors.

- Hydraulic fluid specifications and filter replacement.

Part 13: Cab and Air Conditioning Service

This section addresses the maintenance and repair of the operator's cab and its climate control system.

- Cab filter replacement

- Air conditioning system checks and refrigerant charging procedures.

- Heater system diagnostics.

- Electrical components within the cab.

General Maintenance Purogiramu

Regular maintenance is key to the longevity and reliability of your Massey Ferguson 1105 tractor. Refer to the specific sections for detailed procedures.

| Interval | Basa | Reference Chikamu |

|---|---|---|

| Daily/10 Hours | Check engine oil level, coolant level, tire pressure. | Zvikamu 2 & 3 |

| 50 Maawa | Lubricate chassis grease points. | Chikamu 10 |

| 250 Maawa | Change engine oil and filter. Inspect air filter. | Zvikamu 2 & 3 |

| 500 Maawa | Replace fuel filter elements. Check hydraulic fluid level. | Parts 2 & 3, Parts 11 & 12 |

| 1000 Hours/Annually | Change transmission and hydraulic fluid. Inspect brakes. | Parts 5 & 6, Parts 9, Parts 11 & 12 |

Zvinotsanangurwa

Detailed technical specifications for the Massey Ferguson 1105 tractor, including engine displacement, horsepower, dimensions, and weight, are provided within the relevant sections of this service manual. For quick reference, some general specifications are listed below. Always refer to the specific manual sections for complete and accurate data.

- Muenzaniso: Massey Ferguson 1105

- Mugadziri: Jensales (Manual Publisher)

- Zviyero zvechigadzirwa: Approximately 12 x 10 x 3 inches (Manual dimensions)

- Injini Type: Refer to Parts 2 & 3 for specific engine models (ATC 6.3541, AT 6.3541, AV 8.540)

- Transmission Types: Multi-Power, 8-Speed (Refer to Parts 5 & 6)

Ruzivo Rwokutsigira

For additional support, clarification on manual content, or inquiries regarding this Jensales service manual for the Massey Ferguson 1105 tractor, please contact the publisher directly.

Muparidzi Jensales

Refer to the manual's cover or publisher's webwebhusaiti yeruzivo rwemazuva ano rwekuonana nevanhu uye zviwanikwa zverutsigiro.